High pressure tanks, steam boilers, industrial reactors, and chemical process enclosures are

usually built to standard engineering codes such as ASME Boiler Code or equivalent.

PPC is the industry's leading provider of circular sight glasses that are specifically designed for observation

into such vessels. Our Model B Flange and Model I Flange offer the highest service temperature (1,100 degrees Fahrenheit with fused

quartz lens; Pyrex, soda lime and other glasses also available) and pressures (600+ PSI) in the industry. ANSI Flange dimensions are standard;

DIN or other dimensions can be specified.

Technical Issues for High Temperature/Pressure Service

There are four primary technical issues associated with operating at high temperature and pressures--softness of high temperature glass, stiffness of high temperature gasket/seal materials, thermal expansion of joints, and dangers of re-sealing at high temperature.

- Glass loses strength exponentially as its temperature exceeds its normal service temperature. Soda lime glass should not be used above 450 degrees Fahrenheit (232 degrees Celsius) and borosilicate not above 570 degrees Fahrenheit (300 degrees Celsius). We rate both types for no more than 450 degrees Fahrenheit. For higher-temperatures up to 1,800 degrees Fahrenheit, fused quartz/silica are used. These glasses are much weaker than commercially available tempered silicate glasses, so they have to be thicker. More importantly, they are less tolerant of excessive sealing stresses from gaskets.

- At temperatures over 450 degrees Fahrenheit, commonly available polymer materials cannot be used as gaskets or packings to seal. Harder, metal or graphite based gaskets or packings have to be used. While these materials tolerate higher temperatures well, their relative stiffness compared to softer polymer materials means higher sealing stresses have to be imposed. This higher required sealing stress makes for a dangerous combination with the softer higher temperature glasses if conventional gaskets are used to seal. Graphite based materials may 'burn out' some of their binder mass, resulting in a volume reduction, and requiring in-situ resealing.

- Thermal expansion of joints, including sealing joints, will cause leaks to develop as the unit temperature rises. Even over the commonly available 450 degree Fahrenheit range, thermal expansion is significant enough to cause serious problems for sealing in most commercially available sight glass windows. Because of the thermal expansion, the sight glass units need to be sealed at their maximum service temperature, which usually means resealing in-situ as the unit reaches its service temperature. Worse yet, as the hot-sealed unit cools, the contraction of metal will create enormous stresses on the gaskets and glass, exacerbating an already problematic situation.

- With conventional gasket seals applied on the face of the glass window, this in-situ sealing will have be accomplished by tightening the flange bolts; excessive bolt torque will crush the softer high temperature glass, making the whole process inherently dangerous.

Our proprietary side wall sealing mechanism was developed to overcome these problems, and enable the use of softer high temperature glasses with harder high temperature sealing materials.

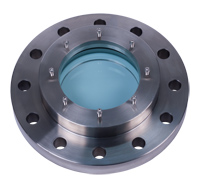

Model B Flange Details |

Model B Flange: High-Temperature/Pressure Applications

Our standard offering for high pressure/temperature service is the Model B Flange. It features our proprietary side wall sealing with an independent compression ring. The sealing is accomplished by compressing the packing material that surrounds the side wall of the glass. This mechanism allows for the use of a greater volume of packing material than can be done with sealing gaskets, as well as the ability to safely and easily re-seal a sight glass in-situ. In turn, this greater packing volume is able to compensate for the relative stiffness of the higher-temperature sealing materials. The ability to reseal in-situ is also a great maintenance saver, as it reduces the requirement for pre-emptive replacements of parts. Standard glasses are rated for up to 450 degrees Fahrenheit and 600 PSI, but much higher temperatures and higher pressures can be provided upon request by using higher-temperature components.

This unit is designed to be completely assembled and sealed prior to mounting on the process. At the same time, it allows for in-situ resealing of the sight glass my merely tightening its compression screws. If necessary for some reason, the glass and packing can be replaced without dismounting the whole flange unit.

|

Model I Flange Details |

Model I Flange: Economical Corrosion Resistance in Addition to Temperature and Pressure

This design adds a separate wetted insert so that the stress-bearing flange would be isolated from the process fluid. This allows the use of cheaper materials for the bulk of stress-bearing flange mass, while the insert can be made of exotic materials or be specially treated with necessary coatings in order to withstand specific corrosion environments. Like the Model B, this unit is sealed along the side walls of the glass lens by packing materials through the use of an independent compression ring.

While its design is specifically to minimize the use of exotic materials required for very corrosive environments, it will accommodate the high temperature materials and components and offer high temperature and pressure ratings like the Model B. |

|